Paper Pumps and Pulp Pumps

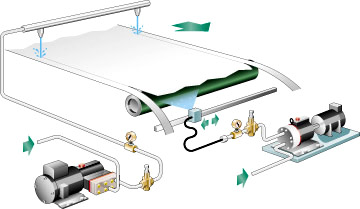

Trim Squirt

In the "wet end" or former section of a paper machine the width of the web of paper is determined. A pair of trim squirt nozzles are used to focus a high pressure jet of water on either side of the web to trim the edges. The cut edges are separated from the rest of the web with "knock-off showers" which are placed beneath and force the edges off the wire and back into the broke chest. In the broke chest, the material is mixed into pulp and reused.

The trim squirt application is critical because it determines the width of the finished product and helps maintain the integrity of the web. At this early stage in the process, the wet pulp hasn't been through either the press section or dryer. Even a slight irregularity, interruption of flow or flawed edge can cause the entire web to rip, forcing the machine to be shut down, cleaned and re-threaded. This is time consuming and very costly.

The Hydra-Cell® paper pumps and pulp pumps provide a pulse free reliable flow to the trim squirt nozzles. The Hydra-Cell® paper pumps and pulp pumps are far more efficient than the centrifugal counterparts often used in the application. A 1/2 HP motor can provide the same required flow and pressure as a centrifugal needing as much as 5 HP. In a 24 hour/7 day a week operation, the savings are substantial. The ease of maintenance and low cost of parts offer other advantages.

Scan-jet

Some mills use a high impact fan nozzle that travels the width of the fabric for cleaning. Because the nozzle reciprocates, it uses a fraction of the water that conventional stationary manifolds use. The Hydra-Cell® paper pumps and pulp pumps are a perfect fit due to its reliability and pulse free-flow. The Hydra-Cell® paper pumps and pulp pumps are far more efficient and easy to repair than the pick-up tube or high speed turbine pumps that are often used.

Chemical injection

All sorts of chemicals are metered in various points in the paper making process. Hydra-Cell® paper pumps and pulp pumps can handle aggressive chemicals because of the choices of materials available and, being seal-less, will pump abrasives without damage. Conventional diaphragm metering pumps often pulse causing damage to the piping systems. Applications include: injecting chlorine into the waste water stream; biocides into the "white water", polymer injection and dyes into the head box.

We're in your industry - Please contact us for help!

Articles

Paper mill filter cleaning

(Published in Maintenance & Engineering, July 02)

Hydra-Cell Seal-less Pump Advantages

Hydra-Cell is a positive displacement diaphragm pump that features a seal-less design to offer significant performance benefits for pump users.

- No seals, cups, or packaging to leak, wear, adjust or replace. This minimizes downtime and reduces yearly maintenance costs.

- Seal-less design makes Hydra-Cell an environmentally friendly pump because there is no leak path or undesirable emissions.

- Hydra-Cell pumps can run dry indefinitely without damage. This eliminates downtime and repair costs.

- Patented diaphragm protection (for most Hydra-Cell models) allows the pump to operate in case of a closed or blocked suction line due to an accident or operator error.

- Unique seal-less, diaphragm design and check valve orientation enable the pump to handle abrasives and particulates up to 800 microns in size (depending on model). This can eliminate the need for expensive fine filtration.

- Pumps the full spectrum of low-to-high viscosity fluids.

- Accurate control of the flow rate by varying the pump speed over a wide range of discharge pressures and fluid viscosities.

- Tolerates non-ideal operating conditions.

- Available with an assortment of materials to resist corrosion, chemical attack, and abrasive wear.

- Mechanical efficiencies of 80 to 90% provide significant energy savings compared to other pumping technologies.

- Simple, compact design with rugged construction provides a wide range of installation options that reduces acquisition and operating costs.

- Maximum flows range from 8 gallons per hour (gph) to 157 gallons per minute (gpm) with discharge pressures up to 5000 psi depending on model. (See “Model Lookup” for details.)

- Low NPSH requirements allow for operation with a vacuum condition on the suction – positive suction pressure is not necessary.

- Hydraulically balanced diaphragms handle high pressures with low stress for longer pump life.

- Multiple-diaphragm design (except the F20 and P100) provide virtually pulse-free flow without the need for expensive pulsation dampeners.