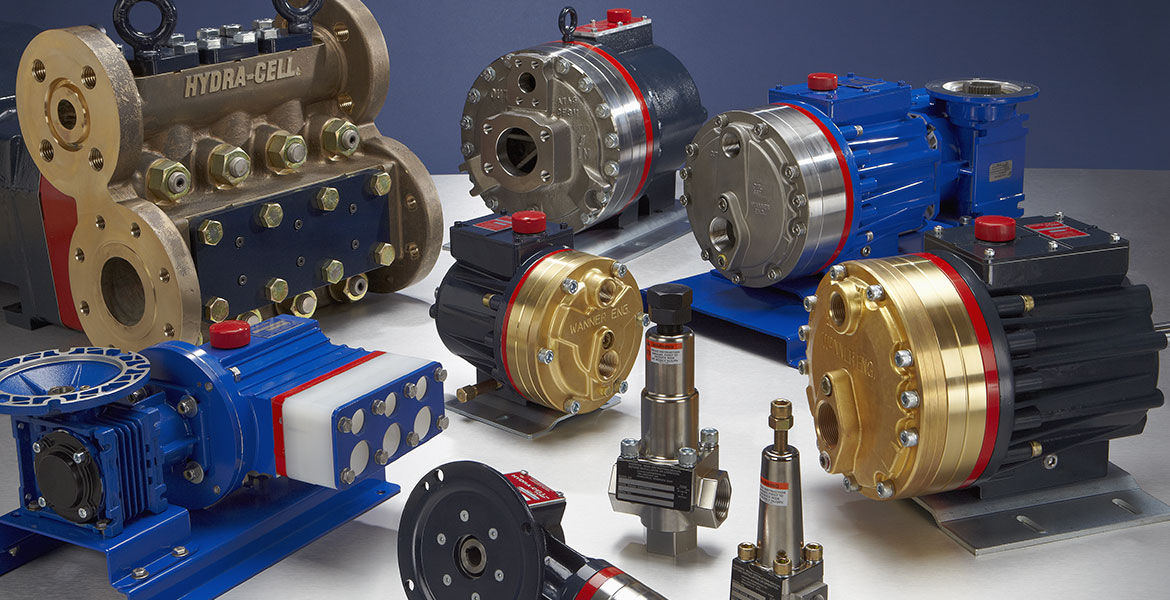

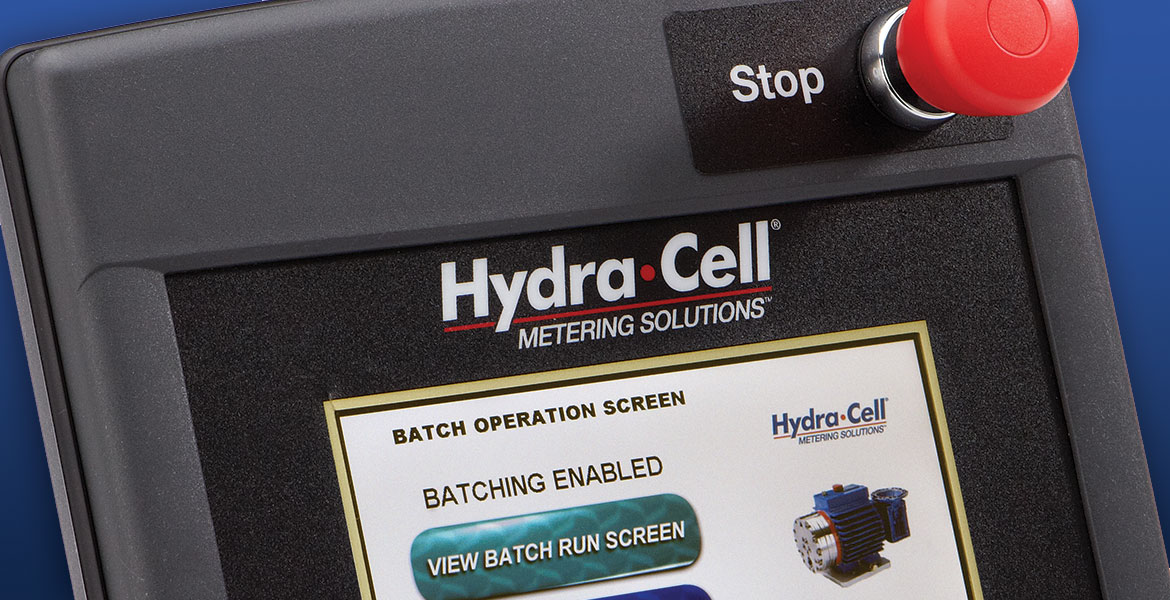

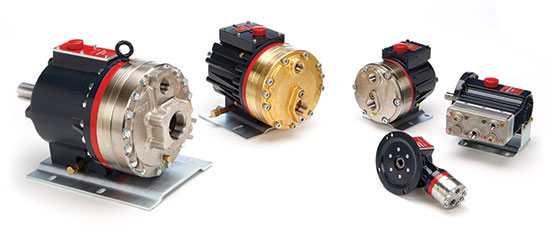

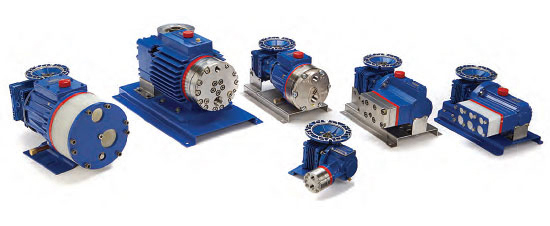

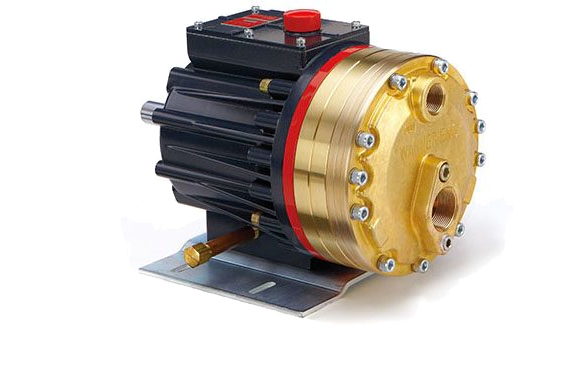

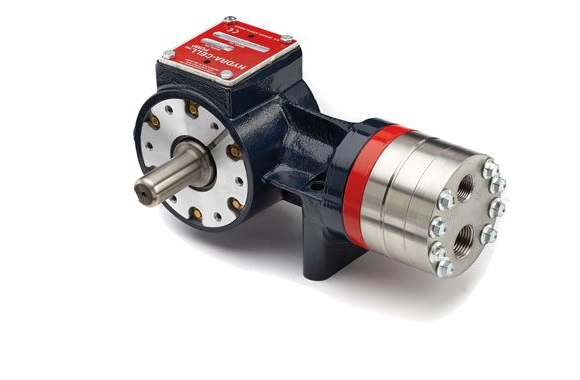

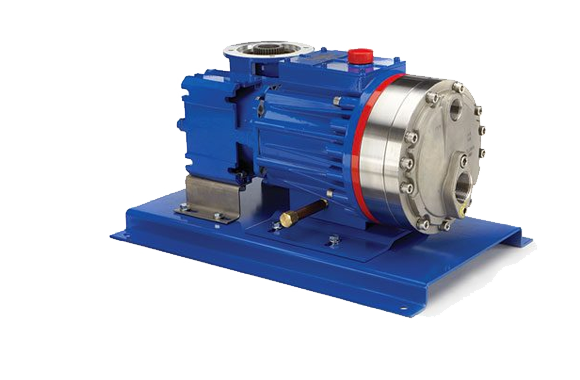

Hydra-Cell positive displacement pumps feature a sealless pumping chamber and hydraulically-balanced diaphragm design, enabling the pumps to provide leak-free, low-maintenance performance while processing difficult fluids over a wide range of pressures and flows.

When we say “Simply Built to Last”, we mean it!