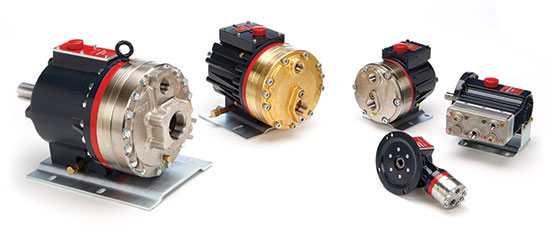

Sealless Pumps

Chosen for their unique design, low maintenance costs, and reliability, Hydra-Cell sealless pumps are used world wide in process applications - in chemicals, oil and gas, pulp and paper, steel, cement, mining, power generation and the food and drink industries.

Applications calling a sealless pump and pressures above 10 bar include:

- Pressure cleaning systems

- Spray coating

- Spray drying

- Forced lubrication

- Flue gas control

- Pressure injection

- Machine tool coolant systems

- De-burring

- Pressure boost

- Pressure testing

Common fluids pumped by Hydra-Cell® Sealless Pumps include:

- Abrasive liquids

- Acetone/glycerine

- Acids

- Adhesives

- Animal fats

- Carbides in alcohol

- Caustics

- Ceramic slurries

- Chemically aggressive liquids

- Chocolate

- Colorings

- Detergents

- Dirty detergent solutions

- Dirty seawater

- Dirty solvents

- Edible oils

- Foaming chemicals

- Fuel additives

- Flavorings

- Inks

- Latex

- Machine tool coolants

- Paints

- Plastics

- Polymers

- Pulp fiber

- Reclaimed or other liquids containing particles

- Resins

- Sand water

- Slurries

- Sugar solutions

- Thin and non-lubricating liquids

- Varnishes

- Volatile fluids

- Waste water

- Water jetting

- Water misting

- Weather-proofing solutions

- Wettable powders

We're in your industry - Please contact us for help!

Hydra-Cell Seal-less Pump Advantages

Hydra-Cell is a positive displacement diaphragm pump that features a seal-less design to offer significant performance benefits for pump users.

- No seals, cups, or packaging to leak, wear, adjust or replace. This minimizes downtime and reduces yearly maintenance costs.

- Seal-less design makes Hydra-Cell an environmentally friendly pump because there is no leak path or undesirable emissions.

- Hydra-Cell pumps can run dry indefinitely without damage. This eliminates downtime and repair costs.

- Patented diaphragm protection (for most Hydra-Cell models) allows the pump to operate in case of a closed or blocked suction line due to an accident or operator error.

- Unique seal-less, diaphragm design and check valve orientation enable the pump to handle abrasives and particulates up to 800 microns in size (depending on model). This can eliminate the need for expensive fine filtration.

- Pumps the full spectrum of low-to-high viscosity fluids.

- Accurate control of the flow rate by varying the pump speed over a wide range of discharge pressures and fluid viscosities.

- Tolerates non-ideal operating conditions.

- Available with an assortment of materials to resist corrosion, chemical attack, and abrasive wear.

- Mechanical efficiencies of 80 to 90% provide significant energy savings compared to other pumping technologies.

- Simple, compact design with rugged construction provides a wide range of installation options that reduces acquisition and operating costs.

- Maximum flows range from 8 gallons per hour (gph) to 157 gallons per minute (gpm) with discharge pressures up to 5000 psi depending on model. (See “Model Lookup” for details.)

- Low NPSH requirements allow for operation with a vacuum condition on the suction – positive suction pressure is not necessary.

- Hydraulically balanced diaphragms handle high pressures with low stress for longer pump life.

- Multiple-diaphragm design (except the F20 and P100) provide virtually pulse-free flow without the need for expensive pulsation dampeners.