Slurry Duty Pumps

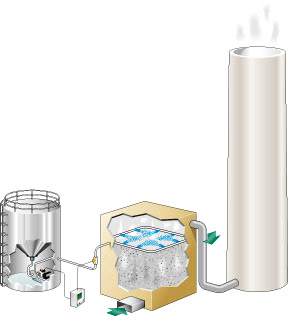

A leading builder and operator of waste-to-energy burning facilities began looking for an alternative and efficient method for the delivery of lime slurry used in Flue Gas Desulfurization. The traditional method was to use 5% lime slurry and 95% water sprayed into the emissions tower creating a barrier for the emission to travel through. The lime slurry would then attach to the sulfur and drop to the bottom of the tower, and the water was used to cool the temperature of the emissions. Existing progressing cavity pumps worked satisfactorily in this application.

The alternative method requires an increase in the solids content of the lime slurry from 5% to 20%. The concentrated lime would significantly decrease the life of their existing pumps. It was time to look for alternative pumps. The Hydra-Cell® slurry duty pump was the slurry duty pump of choice. Not only was the Hydra-Cell® slurry duty pump capable of handling the slurry, but the customer also saw an increase in pump life, as well as a significant reduction in overall maintenance cost.

We're in your industry - Please contact us for help!

Hydra-Cell® Diaphragm Pump Advantages

The seal-less nature of the Hydra-Cell diaphragm pumps enable charged and dirty liquids to be processed without need for fine filtration to protect the diaphragm pump.

The Hydra-Cell diaphragm pump needs little maintenance and can operate at continuous duty at high pressure.

Pulsation is low, so dampeners may not be required for most Hydra-Cell® diaphragm pumps.

Hydra-Cell® diaphragm pumps can handle solids up to 500 microns, or more. They can be pumped without fine filtration. System costs are reduced and maintenance is simplified.

Most diaphragm pumps in the Hydra-Cell® diaphragm pump range can operate at any pressure from <1 bar up to at least 70 bar. Some models up to 170 bar.

Seal-less design distinguishes the Hydra-Cell® diaphragm pumps from other diaphragm pumps and is the basis of its long service life - many of the liquids pumped are harmful to pump seals. The Hydra-Cell® diaphragm pumps are tolerant of small solids, resistant to chemical and corrosive attack.

Energy savings. Compact and highly efficient (80-85%), a Hydra-Cell® abrasive pumps can be fitted with a smaller motor than would be required by many much bigger hot water pumps for equivalent flows and pressures.